AcousticEase-Pet Acoustic Panel Manufacturer

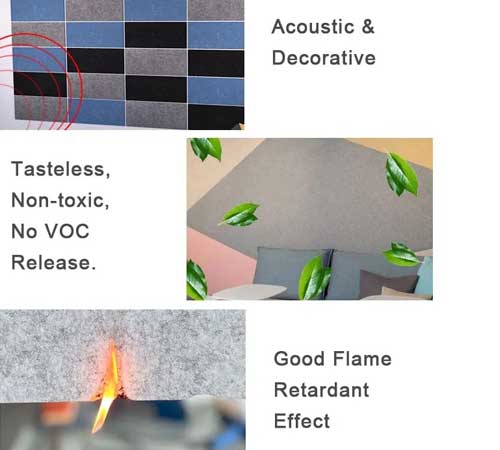

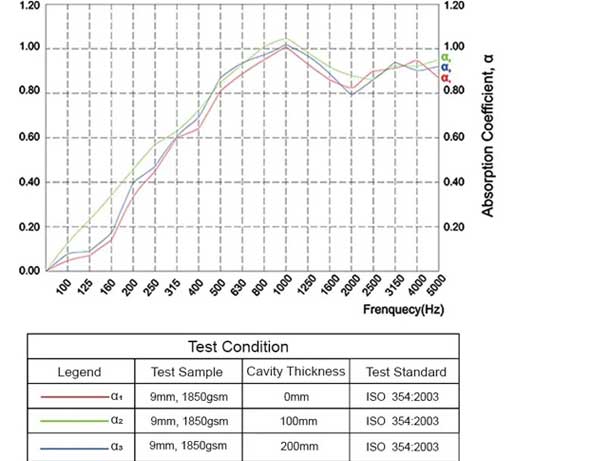

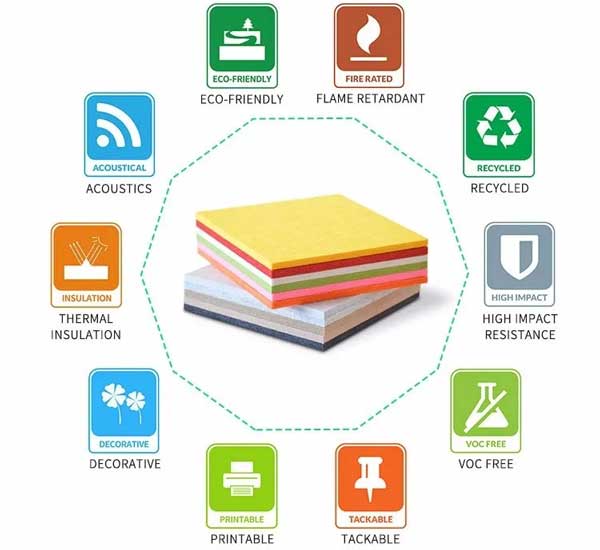

Designed to meet the demanding needs of large-scale construction and interior projects, our PET Acoustic Panels offer superior noise reduction, fire resistance, and eco-friendly materials. These panels are crafted from 100% recycled polyester fiber and deliver outstanding acoustic performance, ensuring optimal sound control for corporate offices, auditoriums, and conference centers. Customizable in size and design, they are the ideal solution for businesses finding functionality and sustainability on a grand scale.

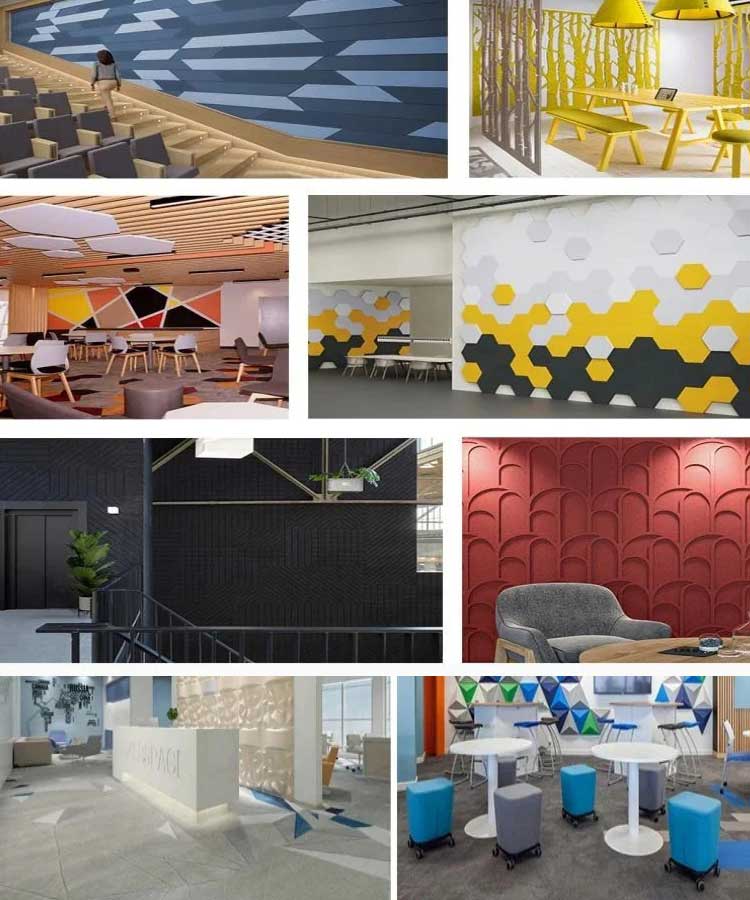

Custom Sound Proof Polyster Pet Wall Acoustic Panel

3D Hexagon PET Felt Acoustic Wall Panel for Recording Studio Polyester

Customized 3D Indoor Sound Isolation Pet Acoustic Panel Office Acoustic Panel

Custom Wall Absorbing Carved Wood Acoustic Art Panel

PET Polyester Wall Panel Cinema Sports Hall Gym Polyester Acoustic Panels

Dust-proof Decoration PET Polyester Fiber Acoustic Panel Eco Friendly Acoustic Panels

Custom Pet Acoustic Panel Polyester Sound Absorbing Ceiling Panels